Chemistry, as a discipline, has always been at the forefront of human progress, yielding groundbreaking discoveries and essential products. However, the process of chemical research and development has often been time-consuming and resource-intensive. This is where AI steps in to make a significant impact.

By leveraging the vast potential of machine learning, data analysis, and predictive modeling, AI empowers scientists and researchers to delve deeper into the realm of chemical formulations and understand the properties and behaviors of compounds like never before.

In this article, we’ll explore the exciting applications and benefits of AI in the chemical industry, ranging from enhancing safety protocols to accelerating research processes. Whether you’re a seasoned chemical engineer, a curious researcher, or a student exploring the frontiers of chemistry, fasten your seatbelt as we embark on a journey to unravel the immense potential of AI in transforming chemical processes. Let’s dive in and discover the remarkable ways in which AI is shaping the future of the chemical industry.

AI in Chemical Formulation

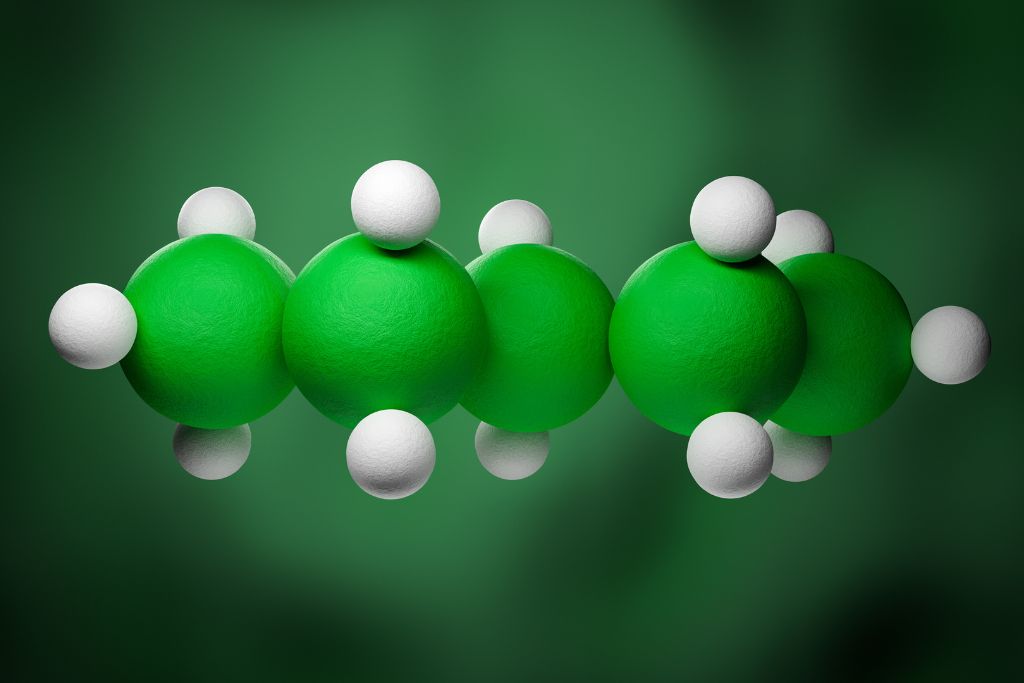

In the realm of chemical formulation, AI’s predictive modeling capabilities have emerged as a game-changer. Traditionally, predicting the properties of compounds required painstaking experimentation and theoretical calculations.

AI algorithms, however, have revolutionized this process by analyzing vast datasets and learning patterns from existing chemical data. By recognizing correlations between various chemical structures and their properties, AI can forecast the behavior of new compounds with remarkable accuracy.

Imagine being able to predict a chemical’s toxicity, stability, and reactivity before even stepping foot in the laboratory. AI makes this a reality, saving valuable time and resources while improving safety standards. This newfound ability to predict chemical properties empowers researchers to focus their efforts on the most promising candidates, accelerating the development of innovative products and processes.

AI-Driven Simulations

Understanding how compounds interact and behave under different conditions is crucial in chemical research. AI-driven simulations offer a powerful tool for gaining insights into complex chemical systems. By simulating molecular interactions and reactions, AI can help researchers visualize and comprehend intricate chemical processes that were once elusive.

These simulations go beyond mere visualizations; they enable researchers to study the effects of changing variables, such as temperature, pressure, and concentrations on chemical reactions. As a result, AI-driven simulations empower scientists to optimize reaction conditions, design better catalysts, or develop sustainable chemical processes.

Accelerating Compound Discovery

Discovering new compounds with desired properties is a challenging and time-consuming task. This is where machine learning comes into play, revolutionizing compound discovery. AI algorithms can analyze vast chemical databases, learn from successful compounds, and identify patterns that lead to specific desired properties.

The ability to rapidly analyze chemical data and propose potential candidates with specific attributes has accelerated the pace of chemical research. AI streamlines the exploration of chemical space, guiding researchers toward novel solutions and pushing the boundaries of innovation.

AI in Chemical Research and Development

AI-Assisted High-Throughput Screening

Research and development in the chemical industry often involve screening an enormous number of compounds to identify those with desirable properties. AI has revolutionized this process through high-throughput screening, enabling researchers to rapidly analyze vast libraries of compounds.

By employing AI algorithms, scientists can sift through extensive databases, identifying potential candidates that meet specific criteria. This accelerates the early stages of research, allowing researchers to focus their efforts on compounds with the highest likelihood of success. AI-assisted high-throughput screening has proven invaluable in drug discovery, materials research, and the development of specialty chemicals.

Machine Learning

The interactions between molecules can be intricate and difficult to predict through traditional means. Machine learning algorithms, fueled by vast datasets, are changing this landscape. AI can analyze chemical data and recognize patterns in molecular interactions, shedding light on complex reaction mechanisms.

This understanding of chemical interactions opens the door to designing more efficient and selective reactions. Researchers can optimize reaction conditions and catalysts, reducing waste and increasing yields. AI’s ability to predict chemical reactions with high accuracy empowers chemists to explore new synthetic routes and unlock novel chemical transformations.

Virtual Experimentation

Traditionally, conducting experiments in the lab is resource-intensive, often requiring substantial time and funding. AI-driven virtual experimentation offers a cost-effective and time-saving alternative. Through sophisticated simulations, AI can mimic real-world chemical reactions and processes in a virtual environment.

Researchers can test hypotheses, explore different scenarios, and predict outcomes without the need for physical experiments. Virtual experimentation significantly reduces the trial-and-error process, allowing scientists to focus on the most promising avenues of research. This approach is particularly advantageous in optimizing reaction conditions, designing materials, and predicting the behavior of complex chemical systems.

AI-Based Drug Design and Materials Discovery

In the pharmaceutical industry, AI has sparked a revolution in drug design and materials discovery. AI-driven algorithms can analyze vast amounts of chemical and biological data, aiding in the design of novel drug candidates with enhanced efficacy and reduced side effects.

Furthermore, AI can identify potential drug targets by analyzing disease-related biological pathways. This approach accelerates the drug discovery process, potentially leading to more effective treatments for various ailments.

Similarly, in materials science, AI has facilitated the discovery of new materials with tailored properties. By predicting the properties of hypothetical materials, AI guides researchers to work on potential candidates first, expediting the development of advanced materials for various applications, such as electronics, energy storage, and aerospace.

AI for Process Optimization

In chemical manufacturing, precision and control are paramount to ensuring the consistency and quality of products. AI-driven process monitoring and control have emerged as indispensable tools in this pursuit. By continuously analyzing real-time data from sensors and production systems, AI can detect anomalies and deviations from optimal conditions.

Through machine learning algorithms, AI can adapt and optimize process parameters in real-time, ensuring efficient and stable production. This not only leads to higher product yields but also minimizes the risk of costly errors and safety incidents. With AI at the helm of process control, chemical manufacturers can achieve unprecedented levels of efficiency and product uniformity.

Real-Time Data Analytics

The chemical industry generates vast amounts of data during production, but making sense of this data in real-time has been a challenge. Enter AI-powered real-time data analytics, which unlocks valuable insights from the data deluge.

By analyzing data streams from various stages of production, AI can identify patterns and trends that might have otherwise gone unnoticed. This empowers operators to optimize processes on-the-fly, make informed decisions, and address potential issues before they escalate. Real-time data analytics not only enhances production efficiency but also plays a crucial role in maintaining product quality and meeting regulatory standards.

AI-Based Predictive Maintenance

Equipment failures and unplanned downtime can have severe repercussions in chemical manufacturing. AI-based predictive maintenance offers a proactive solution to this challenge. By monitoring the condition of machinery and equipment through sensors and historical data, AI can predict when maintenance is needed before a breakdown occurs.

Predictive maintenance allows maintenance teams to perform repairs and replacements at the most opportune times, minimizing production disruptions and reducing maintenance costs. It also extends the lifespan of critical assets, leading to better resource utilization and increased overall efficiency.

Optimization of Energy Consumption & Resource Utilization

The chemical industry consumes a massive amount of energy and resources. However, AI comes to the rescue by enabling the optimization of energy consumption and resource utilization. By analyzing historical data and considering external factors, such as weather and market demand, AI can develop models to predict energy usage patterns.

These models help manufacturers implement energy-efficient strategies, such as adjusting production schedules during off-peak hours or optimizing the use of raw materials. The result is reduced energy costs, lower environmental impact, and a more sustainable approach to chemical production.

AI for Safety Enhancement

Safety is crucial in the chemical industry, where handling hazardous substances is routine. AI is playing a crucial role in improving safety standards by conducting comprehensive risk assessments and identifying potential hazards.

By analyzing historical data, process parameters, and environmental factors, AI can predict and evaluate potential risks in chemical processes. This proactive approach allows operators and safety personnel to implement preventive measures and mitigate potential hazards before they escalate into accidents. AI-powered risk assessment adds an extra layer of protection, ensuring the well-being of personnel and the surrounding environment.

Implementing AI for Early Detection of Safety Deviations

Detecting deviations from normal operating conditions in real-time is vital for ensuring safety. AI’s ability to analyze large volumes of data in real-time enables early detection of anomalies that might indicate safety risks.

Through continuous monitoring and machine learning algorithms, AI can flag deviations in process parameters or equipment behavior. This allows operators to take immediate corrective actions, prevent incidents, and minimize the impact on operations. Early detection of safety deviations is a proactive approach that fortifies safety measures, reducing the likelihood of accidents and unplanned shutdowns.

AI-Driven Safety Protocols and Response Systems

In high-risk environments, being prepared for emergencies is crucial. AI can be employed to develop sophisticated safety protocols and response systems to handle emergency situations effectively.

AI algorithms can analyze data from various sources, such as sensors, environmental conditions, and historical incident data, to optimize emergency response strategies. Whether it’s mitigating chemical spills, handling fires, or managing toxic gas releases, AI-driven response systems can help operators make informed decisions swiftly and efficiently. These systems ensure that emergency responses are well-coordinated, minimizing the impact on human lives and the environment.

AI and Sustainable Practices

The quest for sustainability in the chemical industry has led to the integration of AI in designing eco-friendly processes. AI’s ability to analyze vast datasets and optimize complex systems makes it a valuable tool for creating more sustainable chemical processes.

By considering factors such as energy consumption, raw material usage, and waste generation, AI can identify opportunities to minimize the environmental impact of chemical operations. These optimizations lead to more efficient processes that reduce greenhouse gas emissions and promote a circular economy.

AI in Waste Reduction & Resource Conservation Initiatives

AI has proven instrumental in tackling the challenge of waste reduction and resource conservation. Through data analysis and machine learning, AI can identify patterns that reveal inefficiencies and waste generation points in chemical production.

By optimizing process parameters, AI reduces waste generation and maximizes resource utilization. This not only minimizes environmental pollution but also translates into cost savings for chemical manufacturers. AI-driven waste reduction initiatives are paving the way for a more sustainable and responsible chemical industry.

AI in Green Chemistry and Sustainable Material Development

Green chemistry, which focuses on developing environmentally friendly chemical processes and materials, has found a valuable ally in AI. AI-powered analysis allows researchers to explore a vast chemical space and identify greener alternatives with desirable properties.

Through predictive modeling and simulations, AI can suggest more sustainable materials and chemical routes, thereby supporting the transition to eco-friendly practices. This AI-driven approach fosters innovation and facilitates the adoption of green chemistry principles throughout the industry.

AI in Supporting Environmentally Responsible Practices

As the chemical industry embraces sustainable practices, AI plays a crucial role as an enabler. By providing valuable insights, predictive capabilities, and process optimizations, AI empowers chemical companies to make informed decisions that align with environmental responsibility.

Moreover, AI contributes to compliance with environmental regulations by facilitating real-time monitoring, early detection of potential issues, and rapid response to emergencies. By championing environmentally responsible practices, AI becomes a driving force in steering the chemical industry toward a more sustainable future.

AI Ethics and Security in the Chemical Industry

Ensuring Data Privacy and Security

As AI becomes increasingly integrated into chemical research and development, safeguarding data privacy and security is paramount. The chemical industry handles vast amounts of sensitive data, including proprietary formulations, experimental results, and production processes.

To address these concerns, strict data privacy measures must be implemented to protect against unauthorized access and data breaches. Encryption, access controls, and secure data storage are essential safeguards to ensure that confidential information remains protected.

Additionally, collaborations between chemical companies and AI providers should involve clear agreements on data handling and confidentiality to maintain trust and integrity.

Ethical Concerns Related to AI Decision-Making in Chemicals

The use of AI in decision-making raises ethical considerations, especially when it comes to critical aspects of chemical processes. While AI algorithms can optimize efficiency and productivity, their impact on safety, environmental responsibility, and human well-being must be carefully evaluated.

Chemical companies must adopt ethical frameworks that prioritize human safety, sustainability, and social responsibility. Ethical considerations should be integrated into the development and deployment of AI systems, ensuring that AI-driven decisions align with ethical principles and industry standards.

Transparency and Explainability in AI Algorithms for Chemical Applications

As AI becomes more complex, ensuring transparency and explainability in AI algorithms becomes a pressing issue. In the chemical industry, where safety and reliability are important, understanding how AI arrives at its conclusions is crucial.

AI algorithms should be designed with transparency in mind, allowing users to comprehend the reasoning behind their decisions. Explainable AI methodologies can provide insights into how AI arrives at specific predictions or recommendations, empowering researchers and operators to trust and interpret the results.

Navigating Potential Biases & Ensuring Fairness in AI Models

Biases in AI models can inadvertently perpetuate inequalities and impact decision-making processes. In the chemical industry, biases in data or AI algorithms could lead to unintended consequences, affecting both product development and safety protocols.

To promote fairness, chemical companies must rigorously examine their data sources to identify and mitigate potential biases. Furthermore, continuous monitoring and auditing of AI models can help ensure that fairness is maintained throughout the system’s life cycle. Rigorous testing and validation can help uncover biases, leading to improvements in AI models and decision-making.

Future Trends and Challenges

Exploring Emerging AI Technologies in the Chemical Industry

The future of AI in the chemical industry holds exciting possibilities, with emerging technologies poised to revolutionize various aspects of the field. One such technology is quantum computing, which has the potential to solve complex chemical problems and simulate molecular interactions at an unprecedented scale.

Moreover, the integration of AI with the Internet of Things (IoT) could create intelligent, interconnected systems capable of real-time monitoring and control. AI-powered robotics and automation are also on the horizon, streamlining laboratory processes and chemical manufacturing with enhanced precision and efficiency.

Potential Challenges in Adopting AI at Scale and Integration with Existing Systems

While the potential benefits of AI in the chemical industry are evident, adopting AI at scale poses challenges. The sheer complexity of chemical processes and the vast amount of data involved require robust AI infrastructure and computing resources.

Integration with existing systems may present compatibility issues and necessitate substantial investments in technology and training. Additionally, the industry must address the shortage of skilled AI experts capable of developing and implementing AI solutions tailored to chemical applications.

AI’s Role in Shaping the Future of Chemical Research, Manufacturing, and Safety

AI’s role in the chemical industry is poised to grow significantly in the coming years. In research and development, AI will continue to accelerate compound discovery, predict material properties, and enable green chemistry initiatives.

In manufacturing, AI will drive optimization and automation, leading to increased efficiency and reduced environmental impact. Moreover, AI will play an increasingly critical role in enhancing safety through predictive maintenance, real-time monitoring, and intelligent emergency response systems.

Identifying Opportunities for Collaboration & Innovation in AI Applications

To fully unlock AI’s potential, collaboration between chemical companies, research institutions, and AI providers is crucial. Knowledge sharing and open data initiatives can lead to more comprehensive AI models that benefit the entire industry.

Moreover, chemical companies should actively engage with AI researchers and startups to identify novel applications and drive innovation. Public-private partnerships and interdisciplinary collaborations can foster cutting-edge AI technologies tailored to the unique challenges of the chemical industry.

Conclusion

In this journey through AI in the chemical industry, we witnessed the transformative impact of this cutting-edge technology. AI’s predictive modeling capabilities have revolutionized chemical formulation, enabling scientists to forecast properties and behaviors of compounds with remarkable accuracy. AI-driven simulations have illuminated complex interactions and reactions, leading to optimized processes and novel discoveries. Additionally, AI’s role in research and development has accelerated compound discovery and materials design, propelling innovation to new heights.

As we embark on this AI-driven future, it’s essential to remain mindful of the ethical and responsible adoption of AI. Data privacy, transparency, and fairness should be at the forefront of AI integration. The chemical industry must prioritize safety, sustainability, and human well-being in every aspect of AI decision-making. By adhering to ethical guidelines and fostering a culture of responsible AI usage, the chemical industry can set an example for other sectors to follow.

In conclusion, AI’s integration into the chemical industry has ushered in a new era of possibilities. From research and development to manufacturing and safety, AI’s transformative impact has driven efficiency, innovation, and sustainability.

By embracing AI with responsibility, professionals in the chemical industry can lead the way in shaping a future that redefines the boundaries of scientific exploration and fosters a greener and safer world for all. Let us embrace the power of AI, hand in hand with ethical principles, and together, we can build a better tomorrow for the chemical industry and beyond.